Manufacturing Orders

Dyntechs Manufacturing Management simplifies and optimizes the manufacturing process with features such as production planning, material management, work order tracking, resource allocation, and quality control. This comprehensive solution ensures efficient production, reduced lead times, enhanced quality, and improved customer satisfaction.

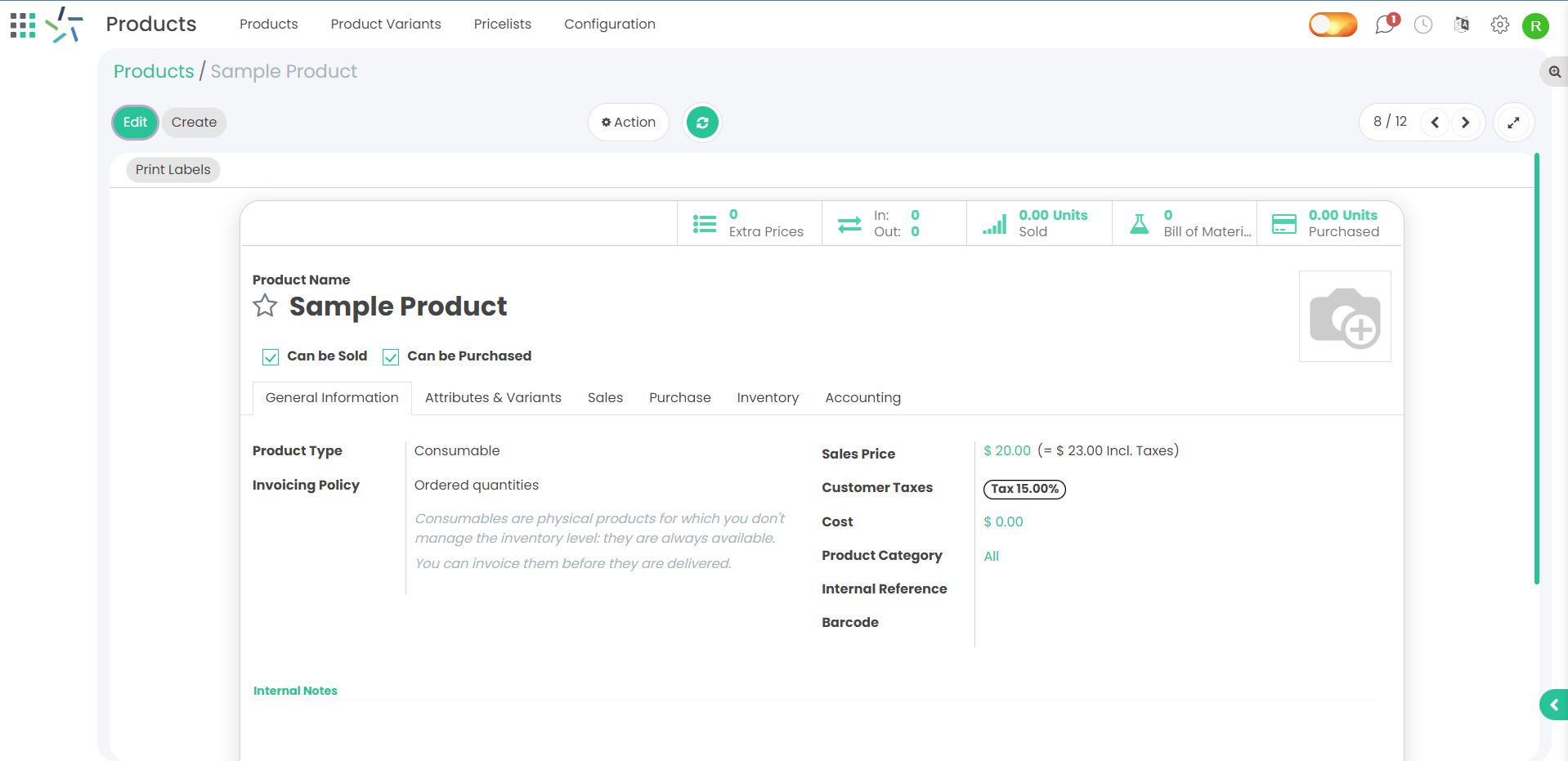

Bills of Materials

Dyntechs Manufacturing Management streamlines the creation and management of bills of materials (BOMs) by providing a centralized system to define and track the components, raw materials, and associated costs required for manufacturing. With accurate and up-to-date BOMs, businesses can ensure efficient production planning, accurate costing, effective inventory management, and seamless collaboration across teams. This results in improved productivity, cost control, and product quality.

Work Orders

Work orders are operations to do as part of a manufacturing order. Operations are defined in the bill of materials or added in the manufacturing order directly.

Scrap Products

Scrapping a product will remove it from your stock. The product will end up in a scrap location that can be used for reporting purpose.

Unbuild Orders

Dyntechs Manufacturing Management allows you to efficiently manage unbuild orders. Unbuild orders are used when you need to disassemble or break down a finished product into its component parts. With Dyntechs, you can easily create and track unbuild orders, ensuring accurate inventory management and traceability of components. This feature helps streamline production processes, optimize inventory levels, and facilitate repairs or recycling of products. By effectively managing unbuild orders, businesses can improve operational efficiency, reduce waste, and enhance overall productivity.